Mon 12 Nov to Sun 18 Nov - Last days in Auxonne

Monday 12 November

We woke to a gloriously sunny, but cold, morning, and Rita rode her bike to Auxonne Gare to take the train to Dijon, while I continued work on the barge. The new flytent is now complete, with the straps over the top to prevent it being removed in the wind, like at Aigues Morte.

But strong southerly winds started to develop in the late morning, which brought a halt to outside work. So I started reading The Gauguin Connection, another novel in the series by Estelle Ryan.

In the afternoon, I went up the BricoMart to do some shopping for items I would need for the remaining work on the barge. In particular, I know I bought several 5m straps in Macon to hold down the tarp cover that I am designing for the cabin roof. But no matter where I look I can’t find them. So I’ve decided to buy some more, and then I’m bound to find them!

Later in the afternoon, the wind had picked up so much that the bimini was lifting and clattering alarmingly. So I put more ropes and straps on it, to hold it firmly to the rear deck railing and stop it lifting. Although strong winds in the past in Moissac have lifted the bimini completely off the barge, that was before I started tieing it down. I’m now pretty sure that no wind is likely to lift the bimini off the boat! (hopefully, these are not famous last words).

In the evening, gathering clouds gave rise to a very different sunset, which I enjoyed while cooking a beef curry (the only cuisine I ever learned from my Dad, who was born in India) for dinner for us, since Rita had decided to commute daily to Dijon this week rather than stay at the AirBnB.

Tuesday 13 November

The wind had subsided overnight, but left us with a rainy morning, so I drove Rita to the station for her trip to Dijon.

Later in the morning, I heard, then saw, a commercial barge heading down the Saone. These barges are smaller up here than further south, because of the size limitation imposed by the ecluse just south of Auxonne.

When the rain cleared and the sun appeared, I went for a walk up to the Pont de France, because on the way to the station this morning, a car tooted at me and Rita said I had not given way on a roundabout. I was sure I hadn’t seen any roundabout, but now I was beginning to have my doubts, so I thought I should check. When I got there, I looked around and was satisfied there was no roundabout, but when I went to the eastern approach to the intersection (from where the photo below was taken), I realised what had happened. As you approach the intersection, which leads onto the bridge, your attention is grabbed by the STOP signs on the entrance to the bridge. Most traffic coming off the bridge (like the dark car in the background at the left) swings to their right to go around the Auxonne ring-road. However, some (like the silver car in the middle) turn left around a small island, and it is then that the Give-Way sign, hiding under the flower baskets at the right, comes into play, requiring westbound traffic to give way to traffic turning across their path in front of them. So there is no roundabout here, but the Give-Way sign effectively converts this intersection into a “phantom” roundabout by requiring traffic to give way to the left (since there is no traffic coming from the right on this one-way street). I shall be more cautious in the future!

I then continued on a town walk in the sunny conditions, walking down the river under the rail bridge and then turning left to take the back way to Intermarche.

When I got back to the barge, I fitted new handholds at the side doors to make getting on and off the barge more secure, and to avoid pulling on the door handles when getting on or off.

I then spent the rest of the day making a start on the tarp cover frame. For this I had decided to use four 2.5m curtain rods as the main supports, over which the tarp would be draped. For the rearmost rod near the wheelhouse, I made a bracket with a 2.5cm hole drilled out, and screwed to the wheelhouse timber top frame. The curtain rod (of 2.5cm diameter) then fitted into this bracket, and was secured by a 5cm screw through the side of the bracket and the curtain rod.

The next two supports for the curtain rods were attached to the existing supports that were used for the dogbox flytent. Since the four curtain rods had to create a straight line support for increased strength and stability, there was some experimentation to be done with the height of these supports to get a straight transition between the curtain rods which would also lead in a straight line to the support at the very front of the cabin. This was done by using clamps to create a temporary support bracket at each of these locations, which would later be changed to screwed fixings to the flytent support brackets.

The next two supports (there was an objective of having two supports under each length of curtain rod) were of different design. The first was a simple support with a cross bracket at the bottom to provide sideways stability. Because the longitudinal position of this support could be varied, it was only necessary to get the height of this support approximately correct, and it could then be moved forwards or backwards to get a good fit under the curtain rod to maintain the straight line support. Each curtain rod was joined to the next using black gaffer tape. The next support was complicated by the fact that the mast had to be laid down to fit under the cover tarp, but then it lay directly beneath the curtain rod. So the next support was designed to sit on the mast pole, with side brackets securing it to the mast.

The last three brackets were simple brackets, of varying height, with a cross bracket at the bottom for stability. For all these supports, the straight-line curtain rod was maintained by manual sighting by eye from the bottom to the top of the curtain rods.

I finished the construction of the support system, just as the port swans were coming to say hello for the evening and reminding me to go pick Rita up from the station.

The fog was starting to arrive by the time we got back to the barge, and in the hurly-burly of all that had happened in our days, we both forgot our 19th wedding anniversary!

Wednesday 14 November

It was a foggy morning again, but because it was not raining, Rita again rode to the station to take the train to Dijon. During the morning, I was doing some reading on the DBA Forum and elsewhere about winterising barges in the north, where winters can be much more severe than down south in Moissac. I then went outside as the weather cleared to do some more work on the tarp frame.

As I was doing some adjustments to the tarp frame, I noticed someone on board Quercy next door. So I went over to introduce myself. As we talked, it became clear that he was not the owner of Quercy, but was simply helping him with some work that was needed on the boat’s invertor, and introduced himself as Paul Hayes and explained that he lived on a barge downriver at St Jean de Losne. As we chatted, he asked what I was doing with winterising, and I explained my plans. We also talked about membership of the DBA Board, after he recognised my name from the DBA Member Surveys.

In the early afternoon, Rita arrived home early, explaining that she was not feeling well. She then packed up some textbooks for sending home to Australia and went up to the Post Office to post them. She then went to bed to ward off the migraine that she felt arriving.

Thursday 15 November

The morning arrived with more fog but sun was promised for the afternoon. Rita was feeling better, so she headed off to Dijon. Since I was leaving next week, I booked my train tickets (from Auxonne to Dijon to Lyon to CDG Paris) and my hotel at CDG for the overnight stay before flying out in the morning of 20 November.

In reading more about winterising, I realised that Paul Hayes was the author of much of the advice on the DBA Forum about winterising. Since it was something that needed to be done correctly, I contacted Paul to see whether he would be willing to come along and oversee the job. I would do the work, but with his advice and supervision. To my relief, he agreed to do so, and even agreed to bring the antifreeze and various bits and pieces that he had found useful when doing his own winterising. So we agreed that he would come over on Saturday, after Rita had left for Bern.

Luckily, I saw that the money I had transferred from Australia to our Credit Agricole account via OFX had arrived at the bank, so now I was confident that we could cover the costs of the snow tyres, the winterising and the train and hotel bookings.

In the afternoon, I took down and stored the flytent (since it needed to be removed before the tarp cover could be fitted), I changed our good black mooring ropes for our older, tougher winter ropes, and re-arranged the layout of the folded tarp cover to ensure that it could more easily be draped over the frame, since the tarp cover was relatively heavy and awkward to handle. I then mended Rita’s suitcase with gaffer tape for its final journey - we both think it has only got one more flight left in it before it totally falls apart.

Once again there was no sun today, despite the forecasts - maybe tomorrow!

Friday 16 November

It was again a foggy morning.

Today was the last day of Rita's course, and she expected to be home in the early afternoon.

I went out to shop for some items needed for winterising (such as some hose and jubilee clips), and on the way I saw a heron sitting by the river near the port. I got my camera ready since I knew it would only be a matter of time before he took flight as I approached. And sure enough he did, but this time I had the camera ready to capture a few live shots, which I was later able to edit to get the best frames within the live shot sequences.

Rita got home early as expected, but to my surprise she said she would be leaving later today to avoid the possibility of getting caught up in the “yellow vests” fuel price blockade that were planned for tomorrow. So I quickly got her to help me get the tarp up on deck and draped over the frame. It was a bit awkward, but not as bad as we thought; it would have been impossible single-handed.

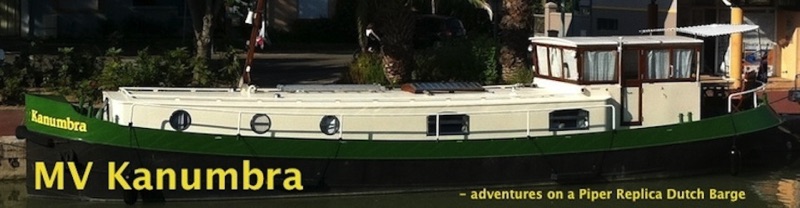

Rita then left to drive to Besain to leave a car key for Albon, then to the Frasne rail station, then by train to Neuchatel and Bern. Albon will later pick up the car from Frasne and take it back to Besain to store it there for the winter, as per last year. As I came back from saying goodbye to Rita at the parking lot, I called in to see John Stevenson at the Port Office to formally register Kanumbra with H2O for the winter (thought it would be a good idea to do that before I leave!).

I then got to work making the bungee-cord and s-hook connectors to secure the tarp to the side-railings. This was a painstaking task, and got a bit awkward as more and more of the tarp was connected to the side-railings and one could no longer walk along the side gutters. I also had to alternate from side to side to ensure that the tarp remained evenly tensioned on both sides. But it was satisfying as it took shape and neared completion. When all the bungee-cord connections were in place, I then put the black straps over the top and secured them to the side railings. I think it looks pretty secure, but will check it periodically via the Port Royal webcam, especially when any strong winds are forecast.

Saturday 17 November

There was no fog this morning, and it was sunny but cold.

Today was the day that Paul would help me do the winterising. I was hoping to get some photos of the process, but Paul kept me working, so all I have is a verbal description of what we did!

The first job to do, well before Paul arrived because it was potentially a very slow job, was to drain the fresh water tank. Luckily it had drained itself just last week, and I had just partially filled it with enough water to last us for the week. So I turned on all the taps in the shower, bathroom and kitchen sinks and waited for it to run dry. After it had spluttered to a stop, I turned off the water pump. I then turned off the shower and the bathroom sink. I turned the pump on again and noticed that more water continued to come out of the kitchen sink tap for a while, until it again stopped. I repeated this about six times until relatively little was coming out the kitchen tap when the pump was turned on, hopefully indicating that most of the pipes were now empty.

The first job to do on the day was to bypass the calorifier (hot water) tank by connecting the inlet pipe directly with the outlet pipe, without going through the calorifier. However, before connecting the inlet and outlet, it was necessary to drain the calorifier through the outlet pipe, a little at a time, so that large quantities of antifreeze would not be needed to protect the calorifier full of water.

The next job was to drain and protect the fresh water systems. Firstly, it was necessary to remove the feed-in pipe from the water tank to the water pump, and replace it with a piece of plumbing hose (easier said than done, getting the new connection onto the plastic thread in an awkward position on the bottom of the water pump). A 60/40 foodsafe antifreeze mix was then made up in a bucket, and with the shower tap open, the antifreeze mix was then sucked out of the bucket into the pump and onto the shower. The shower was allowed to run until the pink antifreeze was flowing freely out of the shower head. The shower was then turned off and the process repeated with the bathroom sink and then the kitchen sink. On each occasion the pink anti-freeze solution was allowed to run for a while until it ran down the drains, into and through the grey water tank (as indicated by the sound of the grey water tank pump operating). The toilet was also flushed three times with pink anti-freeze water into the black water tank. Finally, the washing machine (and then the dishwasher) were filled with a few cupfulls of antifreeze and allowed to run until the existing water in the machines was flushed out and then the cycle started, to fill the inlet and outlet pipes with anti-freeze.

The next job concentrated on the main engine. Firstly, Paul did a hygrometer test on the engine coolant to determine the current level of anti-freeze in the coolant system; and the result was that there was effectively none! This is perhaps not surprising, given that the barge has been in the warmer southern climates for many years. So the first task was to remove about 15 litres of coolant from the engine and associated keel cooling tanks. This was done by disconnecting the inlet hose from the keel cooling tank, and then loosening the cap on the header tank to allow coolant to run out of the system. Once this was done, we added 15 litres of 100% engine antifreeze to the header tank.

Next up was the generator cooling system. Firstly, we closed the generator input sea-cock where raw cooling water is drawn up from the canal. A hygrometer check (looking for a protection temperature of -15degC) showed that, unlike the main engine, the generator antifreeze level was OK, so no more antifreeze needed to be added to the engine itself. But we still needed to protect the cooling water pipes leading to the engine. So firstly, we removed the generator weed-filter cap (checking that there was no excessive weed in the filter), and then started the generator to get cooling water circulating in the system (we had a generator battery problem, which required the use of jumper leads from one of the main engine starter batteries). As soon as the generator started, I poured about 5 litres of 60/40 engine antifreeze into the weed-filter bowl, until the pipes feeding the generator engine were filled. I then stopped the pouring and the engine. I then emptied the contents of the bowl down the input pipe by gradually opening the sea-cock. I repeated this three times until the input pipe was full of antifreeze mixture.

The final main task was to winterise the boiler for the heating system. Firstly, we closed the two input values to the boiler, and removed the connecting hose between the two valves. We then drained the boiler of sufficient water (the same quantity as the amount of antifreeze we were going to add) using the pressure relief control. Next we put the special boiler antifreeze into a garden spray pressure pack, and connected the pressure pack to the boiler inlet. We then pumped air into the pressure pack and hence forced the antifreeze fluid into the boiler. Once all the antifreeze had been pumped into the boiler, we closed the inlet valve and disconnected the pressure pack. We then replaced the connection hose between the valves, and used the inlet value to get the pressure in the boiler up to about 1 bar.

Finally, after all the work was completed in the engine room we started the main engine and let it run, in forward gear, at 1000rpm for 30 minutes to completely circulate the coolant through the engine and keel cooling tanks. We then did another hygrometer check and were satisfied that it was now protected down to -15degC.

After we finished, I arranged to meet Paul in town at the bank, where I had to withdraw money to pay him for all the materials and make a modest contribution for his time. I cycled into town while Paul drove. After I got to the bank and withdrew the money, I waited for Paul and wondered why he had not arrived. A while later, he arrived and explained that he had been stopped by the "yellow vests” at a blockade at the roundabout at the head of the main street (“the girl on the bridge” roundabout), but that he had managed to talk his way through.

All up, it took about 4 hours for the winterising, plus an hour for lunch, so I figured it had been half a day well spent. As evening approached, I sat on the rear deck having a well-deserved beer and watching the sunset.

Sunday 18 November

Today was my last full last day in Auxonne, so there was a bit of tidying-up to do before I left. Firstly, I had to clean up the engine room after the winterising, since there was a bit of spilt antifreeze everywhere. I also wanted to reconnect the inlet hose to the water pump, just so the water tank wasn’t accidentally filled next year without the pump being connected. But getting the inlet pipe back onto the pump was difficult, as had been getting the suction hose onto the pump previously, so I resorted to using my iPhone camera to get a better look at the situation, and it clearly showed that the thread was damaged. But it also showed that there was a clip holding the thread and o-ring in place, so I undid the clip, removed the entire thread and o-ring fitting, and then worked on the thread with a knife to temporarily repair the thread. It was then relatively easy to get the thread into the inlet pipe, and then push the o-ring into the water pump and slide the clip back into place.

The next job was to defrost the fridges, with the aid of a hair dryer to melt the ice around the freezer compartment. I then cleared the cupboards of any opened food packets, and emptied the trash.

I did a final reinforcing of the tarp cover by adding one more strap over the top and attaching two ropes from the rearmost corners back to the rear bollards to ensure that the tarp retained a snug fit against the wheelhouse.

It was then time to store the bikes, rear deck furniture and carpet in the wheelhouse, and finally think about packing my bag for the trip home. Then a final beer as I watched the sunset from the rear deck.

At night, the view of the Auxonne Barracks gave an indication of what we would be missing over winter.